In conversation with Dr. Alexandre Levisse of EPFL

What is the goal of SwissChips?

The SwissChips initiative offers support to Universities and Universities of Applied Science in Switzerland, to carry out research in the field of integrated circuit design, commonly called chips. In Switzerland, we do not have large foundries to manufacture high performance GPU or CPU chips on a grand scale. But we are extremely good at what the Swiss always do well: quality, precision, excellence and openness to the world.

The SwissChips initiative offers support to Universities and Universities of Applied Science in Switzerland, to carry out research in the field of integrated circuit design, commonly called chips. In Switzerland, we do not have large foundries to manufacture high performance GPU or CPU chips on a grand scale. But we are extremely good at what the Swiss always do well: quality, precision, excellence and openness to the world.

We have a vibrant ecosystem of start-ups, a large pool of homegrown companies creating worldwide recognized equipment, embedded systems and chips. There are many Swiss and international leading actors, and blue chip companies establishing R&D centers.

We also have world-class academic and research institutions such as ETHZ, EPFL and CSEM, which are training engineers and scientists on cutting edge techniques and methods, also fostering innovation and technological leadership. Finally, Switzerland hosts open source initiatives in the field of integrated circuits, such as those based at the RISC-V foundation and CERN.

The SwissChips initiative came about when Swiss universities and research institutes lost access to funding from the EU Chip Act and Horizon Europe. There was a need for a transitional measure, to make sure that we could still do research, and have access to advanced technology. This situation highlighted the fact that designing chips is complex and requires continuous investments to stay competitive. This is particularly important as today most of the big countries or groups of countries are investing heavily in semiconductor ecosystems through chip acts. In Switzerland we do have some of the best universities in the world. But if we do not have access to funding for the design and manufacture of chips, we are losing out.

Designing and fabricating a chip involves several aspects. One is gaining access to technologies, to packaging techniques, and to the software used to design a chip.Another is the know-how and experience. In short, the knowledge acquired by designers and their supporting teams. Finally, it requires a modern IT infrastructure, legal compliance and procurement processes, to get it running smoothly. SwissChips allowed us to grow our supporting teams to provide high quality support and enablement services, to ensure successful silicon validation.

You may ask "why is chip fabrication so important?". Having what we call a "silicon proof" of one's ideas is the ultimate way to demonstrate that what you have in mind, and what you do in your research, actually works. Many research ideas never actually pass the filter of fabrication, things often go wrong at this point. Silicon validation allows us to reach Technology Readiness Level (TRL) 3 to 4. If successful, this paves the way to industrialization and commercialization through the spinning-off of start-ups, or technology transfers.

At the same time, what we do in SwissChips is enabling Swiss universities to continue being world-class leaders in their field, by providing funding for research talents. It provides funding for them to prototype, test and verify their breakthrough ideas. In practice we have several technical workpackages on critical areas such as space electronics, sensors, biomedical systems, edge AI, 6G communications and systems-on-chips.

Who is running the SwissChips initiative and how does the collaboration work?

EPFL, ETHZ, and CSEM are the three main participants and team partners of the initiative. Around these three partners, SwissChips is providing support for chip prototyping to Swiss universities and Universities of Applied Science.

Collaboration between Swiss universities is being fostered through two approaches. One is to carry out research projects together between ETHZ, EPFL and CSEM in organised workpackages. The second is about including other Swiss universities in these projects by financially supporting their chips.

We created what we called a pool funding, that universities in Switzerland can apply for. Applications include a proposal document describing the chip they want to make, what they want to achieve, what technology they use and other technical specifications. This document is then studied by an evaluation committee composed of members of Swiss academic institutions involved in chip design. This committee is led by Prof. Mahsa Shoaran from EPFL.

In this way we have already funded the fabrication of seven chips in a year and a half, enabling the applicants to get much more exposure and traction for their research than they would have had without prototypes.

One major aspect of the collaboration is on coordinating the support activities. What we do in my work package, with the team of Dr. Frank Gürkaynak from ETHZ and Dr. Dragan Manic from CSEM, is to get support teams working together to facilitate the exchange of information and experience, in order to solve problems together. We also want to mutualize circuit blocks that have been already designed, and share design methodologies in order to reduce the time it takes to go from a breakthrough idea to a fabricated chip. In practice, we coordinate the technologies and software, fabrication dates, sign multi-party agreements to share technology data and circuit blocks, and evaluate the feasibility of a common multi-university design environment in Switzerland for Swiss Universities.

In numbers, from February 2024, ETHZ, EPFL and CSEM have worked together to fabricate 100 chips, 25 directly funded by SwissChips, all enabled and supported by their supporting teams.

So these chips come from collaborations on many levels?

Yes, most of the chips designed and fabricated in SwissChips are the realization of a scientific collaboration either between research laboratories of the same university, or between groups from several of the SwissChips partners.

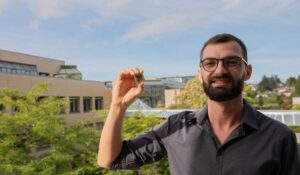

A case example is the Heepnosis chip which was sent for fabrication in February 2025. This chip is a proof of concept of an ultra-low power IoT platform embedding a RISC-V processor as well as various ultra-low power accelerators and on-chip security features.

It has been designed as a collaboration between several laboratories of EPFL and CSEM and fabricated in a 22 nm Fully Depleted Silicon On Insulator (FDSOI) CMOS technology. During the design process, coordination between SwissChips partners paid off, as we could mutualize previous experience and solve together the problems we faced along the way. Finally, the frequency generator used in this chip was designed by ETHZ and easily shared thanks to our multi-party agreements. Overall this enabled a design process to build a 20 million transistor chip in less than ten months.

Another example is the Weisshorn chip supported by pool funding, as a collaboration between EPFL and the University of Basel. This chip used the same technology (22 nm FDSOI) as the Heepnosis chip enabling both design teams to benefit from the work done by the other.

This kind of collaboration between research groups is a holistic process, because they often have extremely innovative ideas that bring the solution of one group to the problem of another. Then they make their chips work together with ideas that they could not have found alone. They may have different specialities, for example radio frequency circuits, analog to digital converters, mixed signal or pure digital design, and together they can make chips that are really innovative. All these circuits can be integrated together through open source platforms such as the X-HEEP platform developed in EPFL.

SwissChips isn’t only about research

The SwissChips initiative is a great opportunity to talk about the field of integrated circuits to the general public. We have been supporting the organization of the Tiny Tape Out Workshop, in which anyone could come and learn about what a chip is, and how to design one. And in the end have the opportunity to actually fabricate a chip that they eventually receive home with a testing board.

Talk about chips is not always easy to understand for non-specialists, and while anyone can hear about GPUs, data centers or chip acts in the press, it is not always easy to see what is behind this, or to understand that all along the road it is about designing and fabricating silicon chips. We intend to continue talking about chips and communicate with high-school students in Switzerland to attract them to our domain in engineering.

More than anything, we want to show that we can do truly innovative work by bringing people together, and that sometimes, the smallest things mean much more than we realize.